product

Weather Resistance Thick Film Powder Fire Resistant Coating

MORE DETAILS

*Product Features:

1. This product is a natural high-refractory inorganic material as the main material. It is made of high-temperature fire-retardant protective coating with a high-resistance fire-resistant limit of 3 hours or more with a polymer binder.

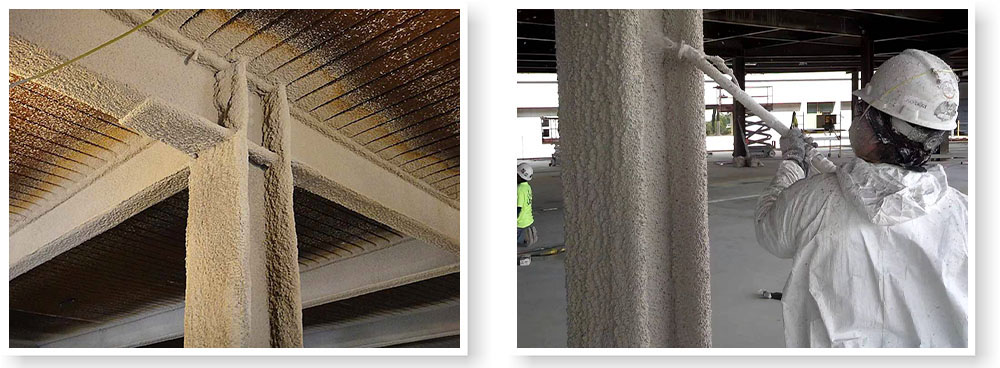

2, the product is a two-component self-drying coating, easy to construct, can be sprayed, smeared.

3. The coating of this product is dry quickly. After 27 days of curing, the coating is dry and resistant to knocking, and has excellent vibration and weather resistance.

4. This product does not contain benzene and asbestos materials. It does not release toxic and harmful substances when exposed to high temperature and is harmless to the human body. The thermal conductivity is low, and the fire resistance limit for steel is more than 3 hours.

*Product Application:

1. Before the construction, the surface of the steel structure should be dedusted, cleaned and completely derusted. Then apply anti-rust paint as required, the thickness of anti-rust paint should be 0.1-0.15mm. Anti-rust paint is generally made of red dan or epoxy zinc-rich anti-rust paint. After wearing anti-rust paint, it is used for NH-II and WH-II outdoor thick steel structure fireproof coating construction.

2. The dry powder main ingredient of the two-component paint and the special binder are mixed with water at a ratio of 1:0.1-0.2:0.8-1, and then uniformly mixed, and then the construction can be carried out.

3. Before the construction, the primer will be brushed or sprayed on the surface of the substrate for 1-2 times. After the surface is dry, the fireproof coating can be applied. The construction can be sprayed or smeared. For the first 1-3 times, the thickness of the coating should be 2-3mm, and the thickness of each coating can be about 5-6mm until the specified thickness is reached. The interval between each construction is 12-18 hours. The air circulation should be maintained at the construction site. The wind speed is not more than 5m/s. It is not suitable for construction when condensation occurs on the surface of the steel structure.

4. For outdoor or in corrosive gas environment, the surface protection coating of the coating should be treated. The protective coating is supplied by the company. The thickness of the overlay is about 0.25mm.

*Technical Datas:

|

No. |

Items |

qualification |

||

|

Indoor index |

Outdoor index |

|||

|

1 |

The state in the container. |

No caking, uniform state after stirring |

||

|

2 |

drying time |

Surface Dry,h |

≤24 |

|

|

3 |

initial dry crack resistance |

1 -3 cracks are allowed, whose width is less than 0.5mm |

||

|

4 |

cohesional strength ,Mpa |

≥0.04 |

||

|

5 |

compression strength,Mpa |

≥0.3 |

≥0.5 |

|

|

6 |

dry density,kg/m³ |

≤500 |

≤650 |

|

|

7 |

Water resistance,h |

≥ 24 h, the coating has no layer, no foaming and no shedding. |

||

|

8 |

Resistance to cold and hot cycle |

≥ 15 times, the coating should have no cracking, no peeling and no foaming. |

||

|

9 |

Coating thickness, mm |

≤25±2 |

||

|

10 |

Fire resistance limit, h |

≥3 hours |

||

|

11 |

Heat resistance, h |

≥ 720 no layer, no shedding, no empty drum, no cracking |

||

|

12 |

Moisture and heat resistance, h |

≥ 504 no layer, no shedding |

||

|

13 |

freeze-thaw resistance, h |

≥ 15 no layer, no shedding, no foaming |

||

|

14 |

Acid resistance, h |

≥ 360 no layer, no shedding, no cracking |

||

|

15 |

Alkaline resistance, h |

≥ 360 no layer, no shedding, no cracking |

||

|

16 |

Corrosion resistant to salt fog,times |

≥ 30 no foaming, obvious deterioration, soften phenomenon |

||

*Construction Method:

Spraying: non air spraying or air spraying. High pressure non gas spraying.

Brush / roll coating: must achieve the specified dry film thickness.