product

Waterborne Epoxy Floor Paint On Concrete Substare

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Technical Datas

- Surface treatment

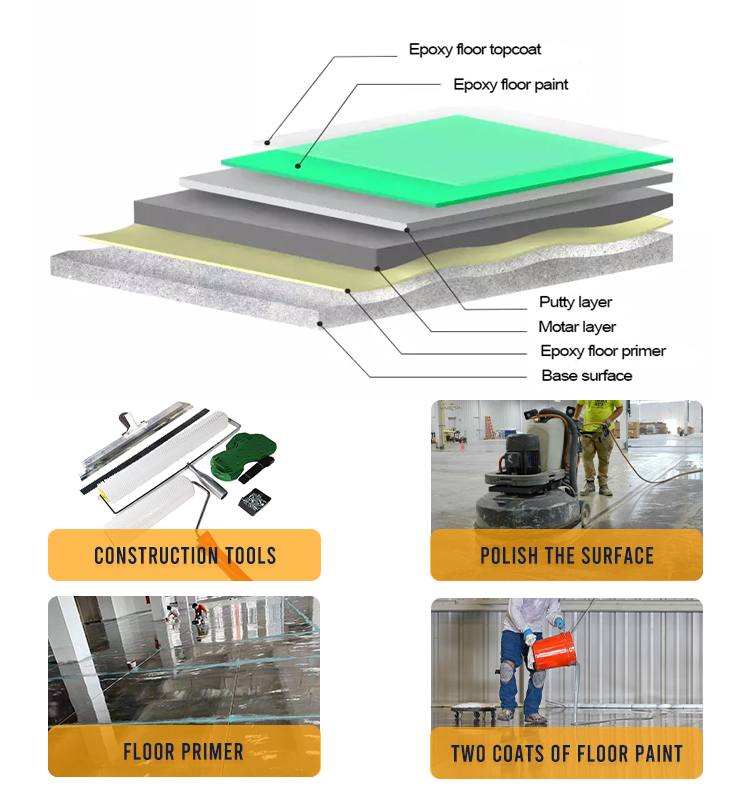

- Construction Steps

- Construction Caution

- Storage And Shelf Life

- Package

*Product Features:

1, The water-based epoxy floor paint uses a water-based undispersed medium, and its odor is smaller than other paints. Its storage, transportation and use are very environmentally friendly.

2, The film is complete seamless and tenacity.

3, Easy to clean, do not gather dust and bacteria.

4, Smooth surface, more color, water resistance.

5, Non-toxic, meets the sanitary requirements;

6, Oil resistance, chemical resistance.

7, Anti slip performance, good adhesion, impact resistance, wear resistance.

*Product Application:

Widely used in electronics factories, machinery manufacturers, hardware factories, pharmaceutical factories, automobile factories, hospitals, aviation, aerospace bases, laboratories, offices, supermarkets, paper mills, chemical plants, plastic processing plants, textile mills, tobacco factories, Surface coating of confectionery factories, wineries, beverage factories, meat processing plants, parking lots, etc.

Widely used in electronics factories, machinery manufacturers, hardware factories, pharmaceutical factories, automobile factories, hospitals, aviation, aerospace bases, laboratories, offices, supermarkets, paper mills, chemical plants, plastic processing plants, textile mills, tobacco factories, Surface coating of confectionery factories, wineries, beverage factories, meat processing plants, parking lots, etc.

*Technical Datas:

|

Item |

Datas |

|

|

Color and appearance of paint film |

Colors and smooth film |

|

|

Dry Time, 25 ℃ |

Surface Dry, h |

≤8 |

|

Hard Dry, h |

≤48 |

|

|

Bend test,mm |

≤3 |

|

|

Hardness |

≥HB |

|

|

Adhesion,MPa |

≤1 |

|

|

Wear resistance,(750g/500r)/mg |

≤50 |

|

|

Impact resistance |

I |

|

|

Water Resistant(240h) |

No change |

|

|

120# Gasoline, 120h |

No change |

|

|

(50g/L) NaOH, 48h |

No change |

|

|

(50g/L)H2SO4 ,120h |

No change |

|

HG/T 5057-2016

*Surface treatment:

Completely remove the oil pollution on the surface of cement, sand and dust, moisture and so on, to ensure that the surface is smooth, clean, solid, dry, non foaming, not sand, no cracking, no oil. Water content should not be greater than 6%, the pH value is not greater than 10. The strength grade of cement concrete is not less than C20.

*Construction Caution:

1. The ambient temperature at the construction site should be between 5 and 35 ° C, the low temperature curing agent should be above -10 ° C, and the relative humidity should be greater than 80%.

2. The constructor should make actual records of construction site, time, temperature, relative humidity, floor surface treatment, materials, etc., for reference.

3. After the paint is applied, the relevant equipment and tools should be cleaned immediately.

*Storage And Shelf Life:

1, Store at the tempestuous of 25°C or cool and dry place. Avoid from sunlight, high temperature or high humidity environment.

2, Use up as soon as possible when opened. It is strictly forbidden to expose to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is six months in the room temperature of 25°C.

*Package:

|

Primer |

Product Name |

Waterbased Epoxy Floor Primer |

Mix Ratio (by weight): |

|

|

Package |

Paint |

15Kg/bucket |

||

|

Hardener |

15Kg/bucket |

|||

|

Coverage |

0.08-0.1kg/square meter |

|||

|

Layer |

1 time coat |

|||

|

Recoat time |

Surface dry- around at least 4 hours to coat midcoat | |||

|

Midcoat |

Product Name |

Waterbased Epoxy Floor Midcoat |

Mix Ratio (by weight): Mix ratio: paint: hardener:water=2:1:0.5 (30% Quartz sand 60 or 80 mesh) |

|

|

Package |

Paint |

20Kg/bucket |

||

|

Hardener |

5Kg/bucket |

|||

|

Coverage |

0.2kg/square meter per layer |

|||

|

Layer |

2 time coat |

|||

|

Recoat |

1, first coat – please wait for full dry arount one night to coat the topcoat2, second coat – please wait for full dry arount one night to coat the topcoat | |||

|

Topcoat |

Product Name |

Waterbased Epoxy Floor Topcoat |

Mix Ratio (by weight): |

|

|

Package |

Paint |

20Kg/bucket |

||

|

Hardener |

5Kg/bucket |

|||

|

Coverage |

0.15kg/square meter per layer |

|||

|

Layer |

2 time coat |

|||

|

Recoat |

1, first coat – please wait for full dry arount one night to coat the topcoat2, second coat – please wait for hard dry then to use around 2 days. | |||