product

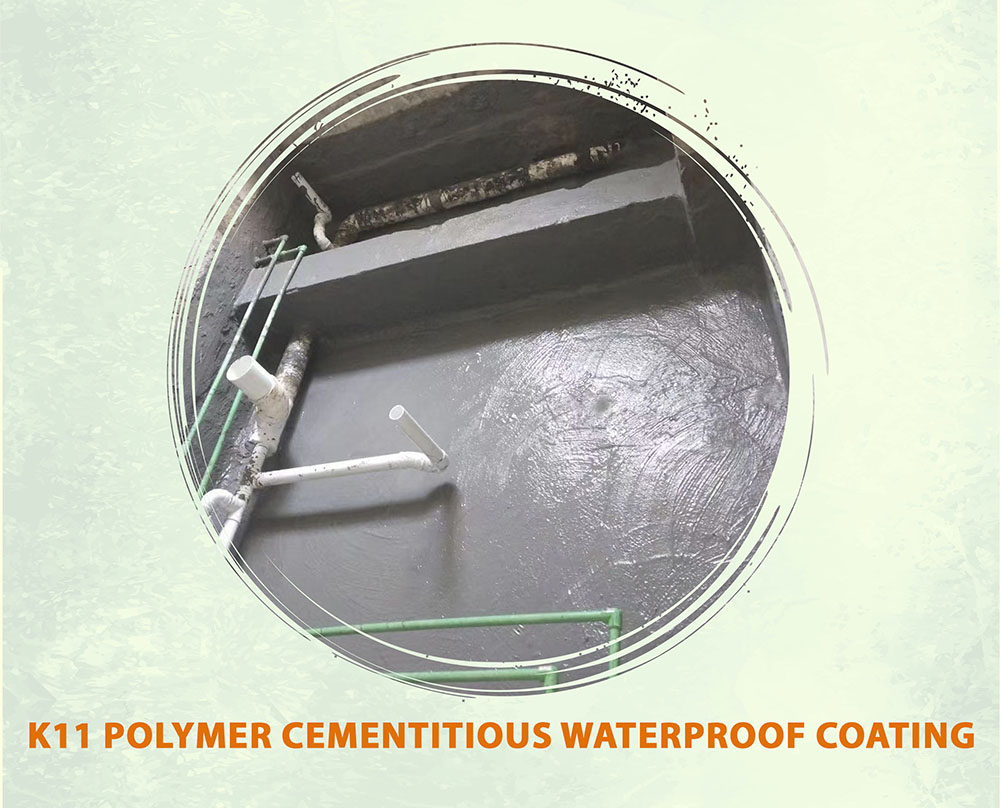

Strong Bonding K11 polymer cementitious waterproof coating

MORE DETAILS

- Product Features

- Product Usage

- Base Preparation

- Product Parameters

- Construction Technology

- Notice

- Transport and Storage

- Package

*Product Features:

1. It can be constructed on wet base surface;

2. Strong adhesion with the substrate, the active ingredients in the slurry can penetrate into the capillary pores and micro-crack wells in the cement base surface to produce chemical reactions. It is integrated with the substrate to form a dense crystalline waterproof layer;

3. After dried and solidified, it is not necessary to make a mortar protective layer to directly paste tiles and other processes;

4. The waterproof effect remains unchanged when used on the upstream or downstream surface of the water;

5. The main component of this product is inorganic material, which has no aging problem and has permanent waterproof effect;

6. Good air permeability to keep the group dry;

7, non-toxic, harmless, environmentally friendly production.

*Product Usage:

Indoor and outdoor mulch structure, cement bottom, waterproof treatment of inner and outer walls, kitchen and bathroom.

Waterproofing of buildings with stable structures such as factory buildings, water conservancy projects, grain warehouses, tunnels, underground parking lots, floor walls, swimming pools, drinking water pools, etc.

*Base Preparation:

1. The substrate must be firm, flat, clean, free of dust, greasy, wax, release agent, etc. and other debris;

2. All small pores and trachoma can be mixed with Kl 1 powder with a little water to form a wet mass, and smooth it out;

3. Before painting the slurry, fully wet the substrate in advance, but there should be no stagnant water.

4. Proportion: Part A slurry: Part B powder, 1:2 (weight ratio) or 1:1.5 according to packaging requirements.

*Product Parameters:

|

No. |

Test Items |

Data Result |

|

|

1 |

Dry Time |

Surface Dry,h ≤ |

2 |

|

Hard Dray,h ≤ |

6 |

||

|

2 |

Osmotic pressure resistance,Mpa ≥ |

0.8 |

|

|

3 |

Impermeability,0.3Mpa,30min |

impermeable |

|

|

4 |

Flexibility,N/mm,≥ |

Lateral deformation capacity,mm, |

2.0 |

|

Bendability |

qualified |

||

|

5 |

Mpa |

None treatment surface |

1.1 |

|

Wet basement |

1.5 |

||

|

Alkali treated surface |

1.6 |

||

|

Immersion treatment |

1.0 |

||

|

6 |

Compressive strength,Mpa |

15 |

|

|

7 |

Flexural strength,Mpa |

7 |

|

|

8 |

Alkali resistance |

No cracking, no peeling |

|

|

9 |

Heat resistance |

No cracking, no peeling |

|

|

10 |

Freeze resistance |

No cracking, no peeling |

|

|

11 |

Shrinkage,% |

0.1 |

|

*Construction Technology:

Pour the powder into a container filled with liquid, stir mechanically for 3 minutes until there is no precipitation colloid, then let it stand for 3-5 minutes, and then stir it again to use. Intermittent stirring should be maintained during use to prevent precipitation. Use a stiff brush, roller or sprayer to evenly brush or spray the mixed slurry on the wet substrate; layered construction, the brushing direction of the second layer should be perpendicular to the first layer; each thickness should not exceed 1mm.

*Notice:

The construction temperature is 5℃-35℃; the slurry after the adjustment needs to be used up within 1 hour; the base surface needs to be re-brushed before the cement calendering base surface is constructed; it is recommended to use ceramic tile bonding when laying tiles on the waterproof layer agent.

*Transport and Storage:

1. Avoid sun and rain, store in dry and ventilated environment.

2. When transporting, it must be placed upright to prevent tilting or horizontal pressure, and cover it with sheet cloth if necessary.

3. Under normal storage and transportation conditions, the storage period is one year from the date of production.