product

Outdoor Decoration Fire Resistant Paint for Metal Industrial

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Technical Data

- Product Construction

- Surface Treatment

- Construction Condition

- Package

*Product Application:

1, can be widely used in hotels, restaurants, shopping malls, conference rooms, theaters, karaoke and other places

2, coated on the surface of wood, glass steel, fiberboard, plywood and other substrates to play a fire retardant effect

*Technical Data:

|

No. |

Items |

Qualification |

|

|

1 |

the state in the container |

No caking, uniform state after stirring |

|

|

2 |

fitness/um |

≤90 |

|

|

3 |

Dry Time |

Surface Dry,h |

≤5 |

|

Hard Dry,h |

≤24 |

||

|

4 |

Adhesion, grade |

≤3 |

|

|

5 |

Flexibility, mm |

≤3 |

|

|

6 |

Impact resistance, cm |

≥20 |

|

|

7 |

Water resistance, 24h |

No wrinkling, no spalling, and basic recovery in standard state for 24 h, allowing for slight loss of light and discoloration |

|

|

8 |

humidity resistance,48h |

No blistering, shedding, slight loss of light and discoloration |

|

|

9 |

flame-resistant time, min |

≥15 |

|

|

10 |

Flame propagation ratio |

≤25 |

|

|

11 |

Mass loss, g |

≤5.0 |

|

|

12 |

Carbonization volume, cm³ |

≤25 |

|

GB12441-2018

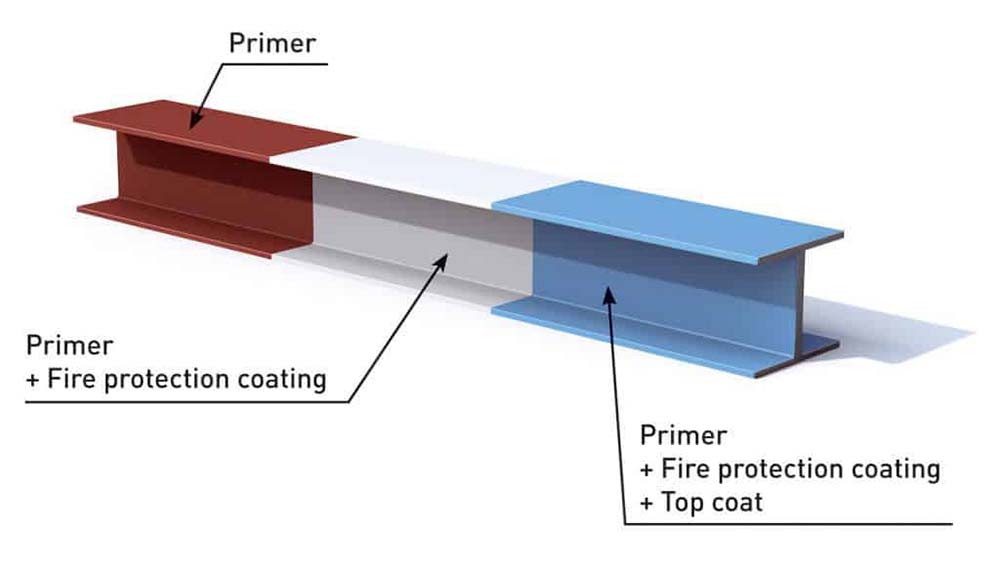

*Product Construction:

1. Remove dust and dirt from the surface of the substrate before construction.

2. When using, stir the paint thoroughly with a stirrer, spray or brush.

3. In order to ensure the adhesion of the coating, it is necessary to dry it before applying the next one.

4. The construction environment temperature is preferably 5-38 ° C, and the relative humidity is <85%.

5. Reference theoretical dosage: 500g/m2.

*Surface Treatment:

- All surfaces must be clean, dry and free of contamination. Before painting, should be assessed and treated in accordance with standard of the ISO8504:2000.

*Construction Condition:

Base temperature is not less than 0℃, and at least above the air dew point temperature 3℃, the relative humidity of 85% (temperature and relative humidity should be measured near the base material), fog, rain, snow, wind and rain is strictly prohibited construction.