product

Oil resistance coatings epoxy anti-corrosion static conductive paint

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Technical Datas

- Construction Method

- Surface treatment

- Transport and Storage

- Package

*Vedio:

*Product Features:

1. The paint film is tough, with good impact resistance and adhesion, flexibility, impact resistance and abrasion resistance;

2. Good oil resistance, corrosion resistance and good electrostatic conductivity.

3. It is resistant to corrosion, oil, water, acid, alkali, salt and other chemical media. Long-term resistance to crude oil and tank water at 60-80℃;

4. The paint film has excellent anti-permeability to water, crude oil, refined oil and other corrosive media;

5. Excellent drying performance.

*Product Application:

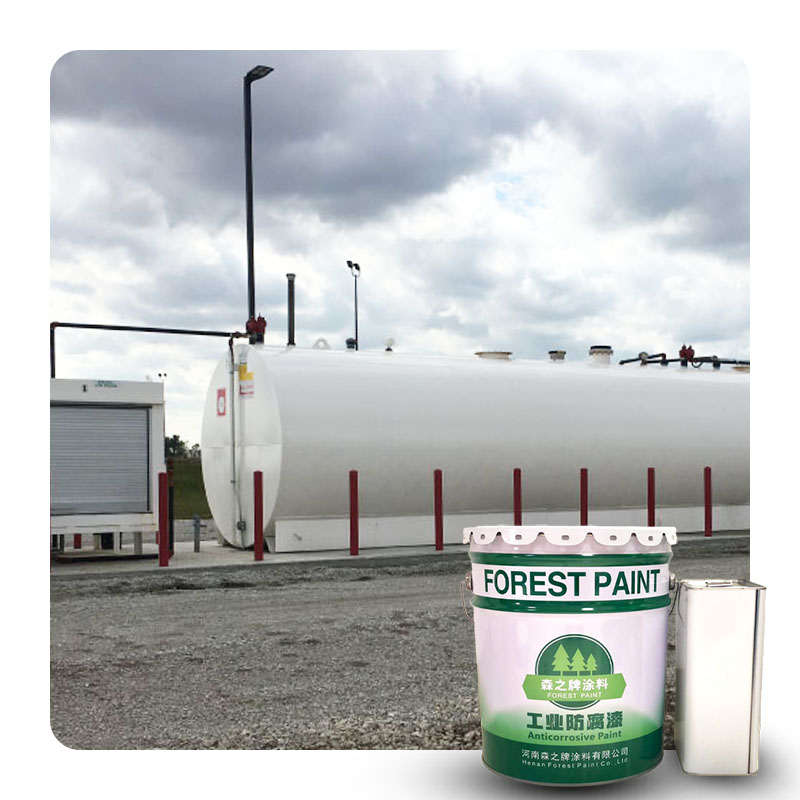

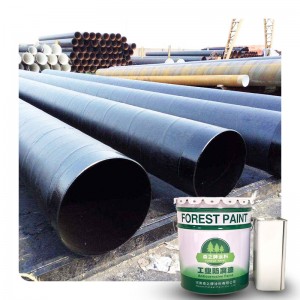

It is suitable for aviation kerosene, gasoline, diesel and other product oil tanks and ship oil tanks and oil tanks in crude oil, oil refineries, airports, fuel companies, port companies and other industries.

Anti-corrosion coating for tank trucks and oil pipelines. It can also be used in other industries where anti-static is required.

*Technical Datas:

|

Item |

Standard |

|

State in the container |

After mixing, there is no lumps, and the state is uniform |

|

The color and appearance of the paint film |

All colors,the paint film flat and smooth |

|

Viscosity (Stormer Viscometer), KU |

85-120 |

|

Dry Time,25℃ |

surface drying 2h, hard drying ≤24h, fully cured 7 days |

|

Flash point, ℃ |

60 |

|

Thickness of Dry film, um |

≤1 |

|

Adhesion (cross-cut method), grade |

4-60 |

|

Impact strength, kg/cm |

≥50 |

|

Flexibility, mm |

1.0 |

|

Alkal resistance, (20% NaOH) |

240h no blistering, no falling off, no rust |

|

Acid resistance, (20% H2SO4) |

240h no blistering, no falling off, no rust |

|

Salt water resistant, (3% NaCl) |

240h without foaming, falling off, and rusting |

|

Heat resistance, (120℃)72h |

the paint film is good |

|

Resistance to fuel and water, (52℃) 90d |

the paint film is good |

|

Surface resistivity of paint film, Ω |

108-1012 |

Executive standard: HG T 4340-2012

*Construction Method:

Spraying: airless spraying or air spraying. High pressure airless spraying is recommended.

Brushing/rolling: Recommended for small areas, but must achieve the specified dry film thickness.

*Surface treatment:

Remove dust, oil and other impurities on the surface of the coated object to ensure clean, dry and pollution-free. The surface of the steel is sandblasted or mechanically derusted.

Grade, Sa2.5 grade or St3 grade is recommended.

*Transport and Storage:

1. This product should be sealed and stored in a cool, dry, ventilated place, away from fire, waterproof, leak-proof, high temperature, and sun exposure.

2. If the above conditions are met, the storage period is 12 months from the date of production, and it can be used after passing the test without affecting its effect;

3. Avoid collision, sun and rain during storage and transportation.