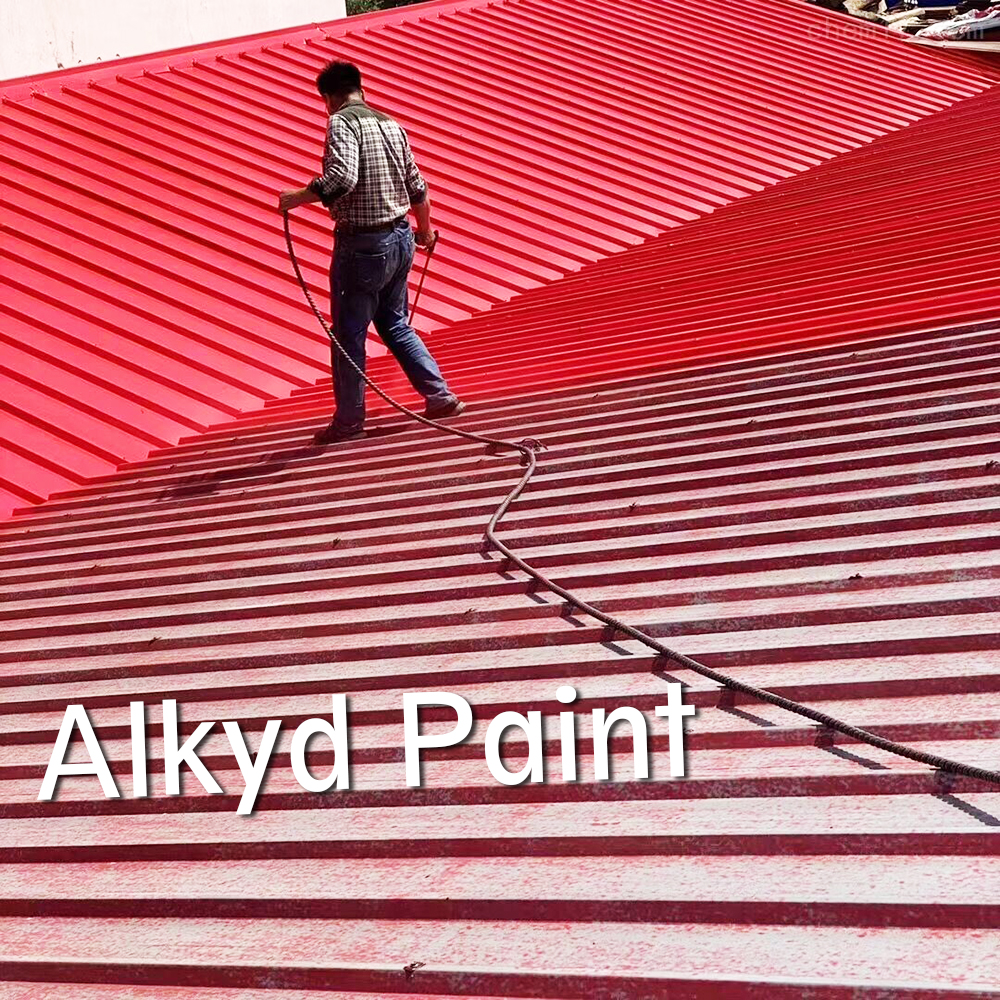

Alkyd anti-rust paint can be used on all types of metals, pipes, mechanical equipment, steel, etc. It dries quickly at room temperature, has good water resistance, high anti-rust performance and good adhesion. The formula is mainly composed of alkyd resin, anti-rust pigments, extender pigments, driers, organic solvents, diluents, etc., and is divided into two types: iron red alkyd anti-rust paint and red tan alkyd anti-rust paint. Iron red alkyd anti-rust paint is an alkyd resin added with iron oxide red and anti-rust pigment fillers. After grinding, add appropriate amount. Made from organic solvents. Suitable for anti-rust primer on steel structure surfaces. The formula of red lead alkyd anti-rust paint is composed of alkyd resin and red lead anti-rust pigment. After grinding, organic solvents and additives are added. Anti-rust coating for steel structure surfaces.

1. It can be constructed by air spraying or brushing.

2. The substrate should be cleaned before use and free of dust, rust, and stains before use.

3. Diluent can be used to adjust the viscosity.

4. When spraying the topcoat, if the gloss is too bright, wait until the previous paint surface is dry or sand it evenly before applying it.

5. When selecting a paint spray gun, keep a distance of 20 cm from the steel surface. The spray gun caliber should be adjusted and the spraying speed should be uniform. Choose a brush to apply. Add the alkyd thinner to the alkyd anti-rust paint and mix well. Choose good quality paint. Brush, the brush is moderately soft and hard, and the force should be even when applying on the surface of the object. After the first coat of paint is completed, it will take about 30 minutes to spray the second coat. Spraying a second coat of paint can increase the thickness of the paint film and improve the anti-rust effect.

Post time: Mar-07-2024