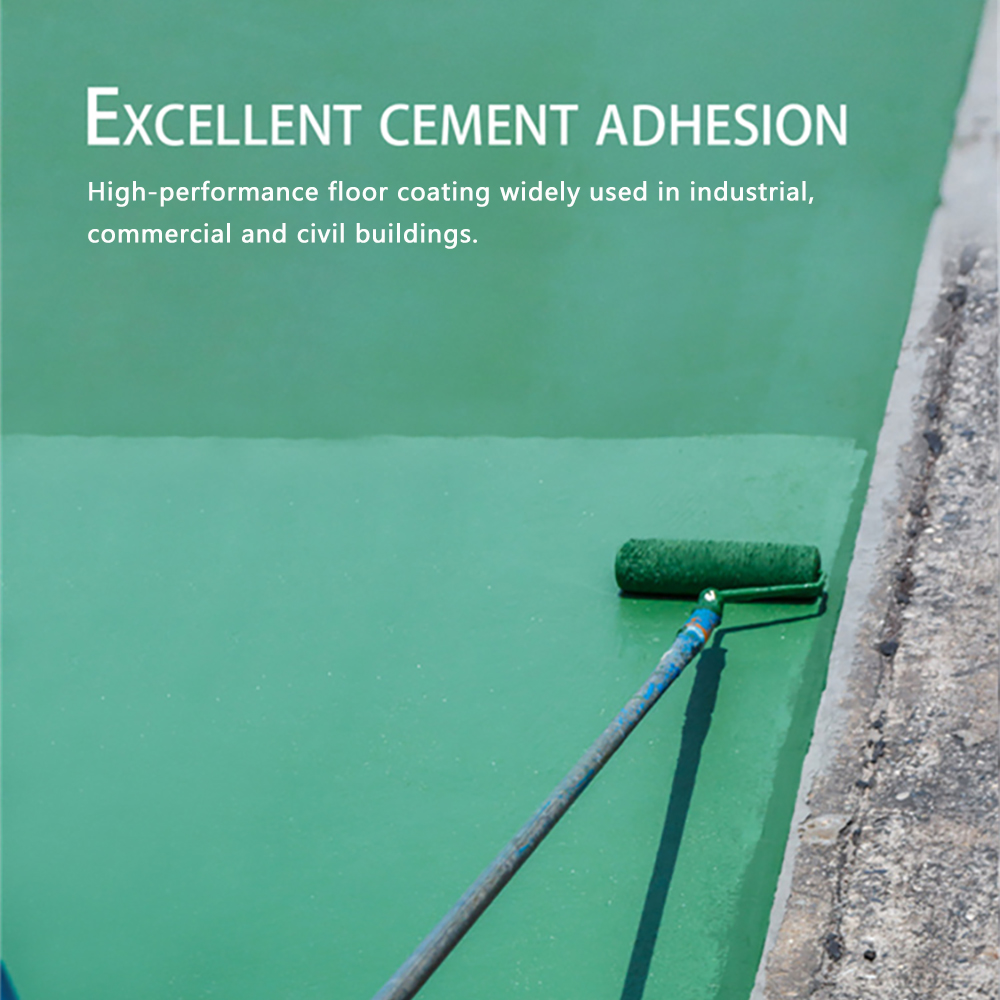

Polyurethane floor paint is a high-performance floor coating widely used in industrial, commercial and civil buildings. It is composed of polyurethane resin, curing agent, pigments and fillers, etc., and has excellent wear resistance, chemical resistance and weather resistance. The main features of polyurethane floor paint include:

Polyurethane floor paint is a high-performance floor coating widely used in industrial, commercial and civil buildings. It is composed of polyurethane resin, curing agent, pigments and fillers, etc., and has excellent wear resistance, chemical resistance and weather resistance. The main features of polyurethane floor paint include:

1. Strong wear resistance: Polyurethane floor paint has good wear resistance and is suitable for high-traffic places, such as workshops, warehouses and shopping malls.

2. Chemical Resistance : It has good resistance to a variety of chemical substances (such as oil, acid, alkali, etc.), and is suitable for environments such as chemical plants and laboratories.

3. Good elasticity : Polyurethane floor paint has a certain degree of elasticity, which can effectively resist minor deformations of the ground and reduce the occurrence of cracks.

4. Aesthetics : Different colors can be prepared according to needs. The surface is smooth and easy to clean, improving the aesthetics of the environment.

Construction steps

The construction process of polyurethane floor paint is relatively complicated and needs to follow the following steps:

1. Base surface treatment

CLEAN: Make sure the floor is free of dust, oil and other impurities. Use a high-pressure water gun or industrial vacuum cleaner for cleaning.

Repair: Repair cracks and potholes on the ground to ensure a smooth base surface.

Grinding: Use a grinder to polish the floor to increase the adhesion of the coating.

2. Primer application

Select primer: Choose a suitable primer according to the actual situation, usually polyurethane primer is used.

Brushing: Use a roller or spray gun to apply primer evenly to ensure coverage. After the primer has dried, check for any missed or uneven spots.

3. Mid-coat construction

Preparing the intermediate coating: Prepare the intermediate coating according to the product instructions, usually adding a curing agent.

Brushing: Use a scraper or roller to evenly apply the mid-coat to increase the thickness and wear resistance of the floor. After the mid-coat is dry, sand it.

4. Topcoat application

Prepare topcoat: Select the color as needed and prepare the topcoat.

Application: Use a roller or spray gun to apply the topcoat evenly to ensure a smooth surface. After the topcoat has dried, check the uniformity of the coating.

5. Maintenance

Maintenance time: After the painting is completed, proper maintenance is required. It usually takes more than 7 days to ensure that the floor paint is completely cured.

Avoid heavy pressure: During the curing period, avoid placing heavy objects on the ground to avoid affecting the quality of the coating.

Temperature and Humidity: Pay attention to the ambient temperature and humidity during construction. The construction effect is usually best under the conditions of 15-30℃.

Safety Protection: Protective gloves, masks and goggles should be worn during construction to ensure safety.

Post time: Sep-27-2024