product

High Efficiency Colorful Decorative Exterior Wall Emulsion Paint

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Surface Treatment

- Technical Datas

- Construction method

- Transport storage

- Package

*Product Features:

1. Good stain resistance, making the coating easy to be cleaned after being contaminated or contaminated.

2, good water resistance: exterior wall paint finish exposed to the atmosphere, will often be washed by rain.

3, good weather resistance: the coating is exposed to the atmosphere, to withstand wind, sun, salt spray corrosion, rain, cold and heat changes, etc., not prone to cracking, chalking, spalling, discoloration and so on.

4, good mildew resistance: exterior wall coatings are prone to mildew in humid environments. Therefore, the coating film is required to inhibit the growth of mold and algae.

5, good decorative: require exterior wall paint color and excellent color retention, can maintain the original decorative performance for a long time.

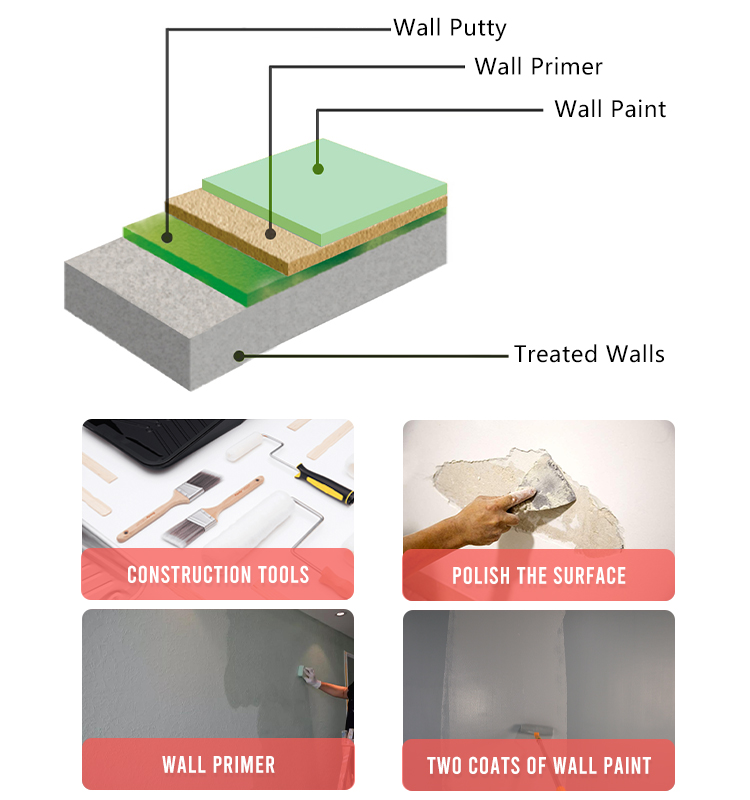

*Surface Treatment:

The surface of the object to be coated should be thoroughly clean, clean and dry. The moisture content of the wall should be less than 15% and the pH should be less than 10.

*Technical Datas:

|

No. |

Item |

Technical Standard |

|

|

1 |

State in a container |

No caking, uniform state after stirring |

|

|

2 |

Thermal storage stability |

Pass |

|

|

3 |

Low temperature stability |

No deterioration |

|

|

4 |

Surface Dry Time,h |

≤4 |

|

|

5 |

Whole Film |

Film appearance |

paint film is normal and has no obvious change. |

|

Alkaline resistance (48h) |

No abnormality |

||

|

Water resistance (96h) |

No abnormality |

||

|

Brushing resistance / times |

2000 |

||

|

Covering fracture capacity (standard state) / mm |

0.5 |

||

|

Acid rain tolerance (48h) |

No abnormality |

||

|

Resistance to dampness, cold and heat circulation (5 times) |

No abnormality |

||

|

Tarnish resistance / grade |

≤2 |

||

|

Resistance to artificial climate aging |

1000 hrs no foaming, no peeling, no crack, no powder, no obvious loss of light, no obvious discoloration |

||

*Construction method:

Brush, roller, spray.

■Substrate treatment | Remove dust, grease, mold algae and other adherents from the painted surface to keep the surface clean, dry and flat. The surface moisture content of the wall is less than 10% and the pH is less than 10. The old wall uses a blade to remove the weak old paint film and remove dust and impurities from the surface, smooth it, and dry thoroughly.

■Construction environment | 5-35 ° C, humidity less than 85%; summer construction to prevent drying too fast, winter construction is prohibited to bake, rain and sand and other extreme weather suspended construction.

■ Recoating time | Dry film 30 micron, 25-30 ° C: surface dry for 30 minutes; hard dry for 60 minutes; recoating interval of 2 hours.

■Tool cleaning | After the painting is stopped and painted, please clean the appliance with water.

■The theoretical consumption of paint | 7-9 m2/kg/single pass (dry film thickness about 30 microns), the amount of paint consumption is different due to the roughness of the actual construction surface and the dilution ratio.

*Transport storage:

Store at a temperature above 5 °C in a cool, dry place below 35 °C, avoid direct sunlight and keep the container tightly sealed. It should be stored separately from strong acids, alkalis, strong oxidants, food and animal feed.