product

Heavy Duty Polyurethane Floor Paint For Building Garage

MORE DETAILS

- Product Features

- Product Application

- Technical Datas

- Surface treatment

- Construction Condition

- Transport and Storage

- Package

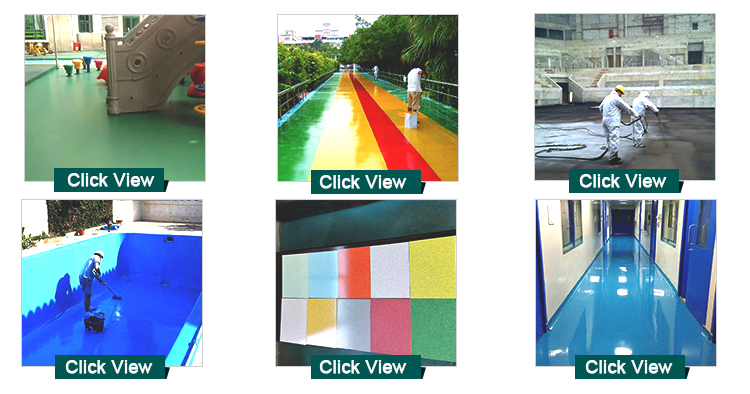

*Product Application:

It is widely used in machinery, food, electronics, chemicals, medicine, tobacco, textiles, furniture, light industry, plastics, cultural and sports goods, etc., and the cement floors or terrazzo floors of manufacturing factories and warehouses. Especially suitable for food processing places and cold storage.

*Technical Datas:

|

Item |

Datas |

|

|

Color and appearance of paint film |

Colors and smooth film |

|

|

Dry Time, 25 ℃ |

Surface Dry, h |

≤8 |

|

Hard Dry, h |

≤48 |

|

|

Usage,kg/m2 |

0.2 |

|

|

Hardness |

≥H |

|

|

Adhesion(zoned method), class |

≤1 |

|

|

Compressive strength, MPa |

≥45 |

|

|

Wear resistance,(750g/500r)/g |

≤0.06 |

|

|

Water Resistant(168h) |

non blister, none fall off, allows slight loss of light, Recover in 2 hrs |

|

|

Oil resistance, 120# Gasoline, 72h |

non blister, none fall off, allows slight loss of light |

|

|

Alkali resistance, 20% NaOH, 72h |

non blister, none fall off, allows slight loss of light |

|

|

Acid resistance, 10% H2SO4, 48h |

non blister, none fall off, allows slight loss of light |

|

*Surface treatment:

The paint must be dry. Remove the dirt, dirt and dust from the paint on the front. No acid, alkali and no water on the film.

*Construction Condition:

The temperature of the base material shall not be less than 0 DEG C, and shall be at least higher than that of the air dew point temperature of 3 DEG C, relative humidity “(temperature and relative humidity should be measured near the bottom of the material), fog, rain, snow, and strong wind conditions shall not be used in the construction of the 85%.

*Transport and Storage:

1. The ambient temperature at the construction site should be between 5 and 35 ° C, the low temperature curing agent should be above -10 ° C, and the relative humidity should be greater than 80%.

2. The constructor should make actual records of construction site, time, temperature, relative humidity, floor surface treatment, materials, etc., for reference.

3. After the paint is applied, the relevant equipment and tools should be cleaned immediately.