product

Epoxy intermediate epoxy floor paint used in warehouse and garage

MORE DETAILS

- Vedio

- Product Features

- Product Application

- Technical Datas

- Matching paint

- Surface treatment

- Construction Method

- Storage And Shelf Life

- Package

*Product Features:

1. Tough paint film has excellent physical properties such as excellent adhesion, flexibility, abrasion resistance and impact resistance;

2, good water resistance, oil resistance, solvent resistance, acid resistance, alkali resistance, seawater resistance, salt spray resistance and other anticorrosive properties;

3, high corrosion resistance and longevity;

4, has good flexibility and impact resistance, can resist deformation caused by external forces, reduce the internal stress generated by the system, and improve the adaptability of the material. ;

5. It has good anti-aging and anti-carbonization performance. The coating can be simultaneously deformed with concrete at different temperature conditions, avoiding excessive interface stress caused by the difference between the expansion and contraction properties of the two materials, which will cause the coating to peel off. Empty and cracked;

6, the main mechanical properties are excellent, the impact strength is 3 to 5 times that of C50 silica fume concrete, and it is firmly bonded to the concrete.

*Product Application:

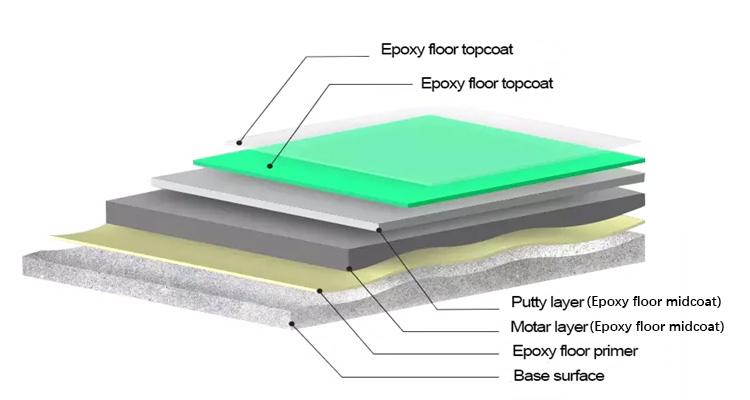

1. Used as an intermediate layer of epoxy floor paint and floor paint to increase the thickness and strength of the entire coating.

2. It is used for projects with poor ground flatness, which can play a role in leveling and repairing.

3. It can also increase the load, wear resistance and impact resistance of the project.

*Technical Datas:

|

Item |

Standard |

|

Color and appearance of paint film |

all color, film formation |

|

Hardness |

≥2H |

|

Viscosity (Stormer viscometer), Ku |

30-100 |

|

Dry film thickness, um |

30 |

|

Drying time (25 ℃), H |

surface dry≤4h, hard dry≤24h, Fully cured 7d |

|

Adhesion (zoned method), class |

≤1 |

|

Flexibility,mm |

1 |

|

Water resistance, 7 days |

no blister, no fall off, little change color |

*Matching paint:

Epoxy floor paint, epoxy self-leveling floor paint, epoxy floor paint, polyurethane floor paint, solvent-free epoxy floor paint; epoxy mica intermediate paint, acrylic polyurethane paint.

*Surface treatment:

The primer should be dry and free of all oil stains and debris.

-

● Pickling method (suitable for oily floors):

Clean the concrete surface with hydrochloric acid with a mass fraction of 10-15%. After the reaction is complete (no more air bubbles are generated), rinse with clean water and brush with a brush. This method can remove the mud layer and obtain a finer roughness. Zh

-

● Mechanical method (suitable for large area):

Use sand blasting or electric mill to remove surface protrusions, loosen particles, damage pores, increase attachment area, and use a vacuum cleaner to remove sand particles, impurities and dust. For the ground with more depressions and potholes, fill with epoxy putty to repair it before proceeding.

-

● Putty repair:

The pits existing on the cement surface layer are filled and repaired with cement mortar, and after natural curing, they are polished and smoothed.

*Construction Method:

Choose the right tool to level the ground by scraping, wiping, rolling, etc., and then sand and smooth it.

The actual amount of paint used during painting depends on the roughness of the surface being coated, the thickness of the paint film, and the loss of painting, and is 10% -50% higher than the theoretical amount.

*Storage And Shelf Life:

1, Store at the tempestuous of 25°C or cool and dry place. Avoid from sunlight, high temperature or high humidity environment.

2, Use up as soon as possible when opened. It is strictly forbidden to expose to the air for a long time after it is opened to avoid affecting the quality of the products. The shelf life is six months in the room temperature of 25°C.